These premium packaging boxes are probably the most common type of packaging out there. In the world of packaging, they are also known as the 'set-up' boxes, mostly made out of cardboard. The significant difference between a rigid box and a cardboard box is the overall box thickness. According to careful estimations, the rigid boxes are four times thicker.

The making of a rigid box is the same as that of a cardboard box. They usually come in sections that can be easily assembled later on. Think of a classic shoebox. That is precisely what a rigid box usually looks like, but with a thick structure.

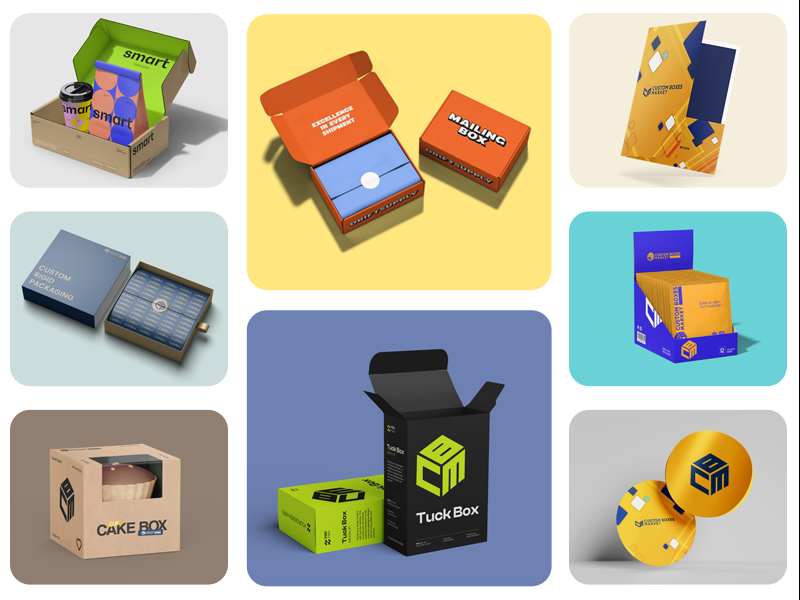

Whenever we talk about a rigid box, we talk about quality and precision. TPS offers some amazing types that can lure customers to you. Let's talk about them.

Probably the class of boxes used by almost every other retailer on the planet. The telescope boxes have two subclasses as well. The first one is the full telescope lid box, and the second is the partial telescope lid.

As the name indicates, the full telescope boxes come with a full covering lid. Our custom printed rigid boxes with full telescopic lids cover the whole base of the box. Retailers generally use these types of boxes for chocolate packaging. On the other hand, the partial telescope boxes come with lids that partially cover the base.

Time to dive right into luxury. The hinged lid rigid boxes are generally used to enclose premium end products like wallets, perfumes, watches, and even jewellery. The overall build dynamics of these boxes are super elegant—the very reason why most luxury brands prefer going with the boxes.

Two main models of the lid are integrated within a hinged lid box. The first model includes a lid hanging freely under the influence of gravitational forces. A magnet is usually used to keep the lid attached to the box. The other lid model is the ribbon-made hinged model itself.

Flexibility is something out of the discussion in the whole concept of rigid boxes. We usually use such luxury boxes for packaging more luxury goods on a more productive level; the boxes store goods that need more safety from the external environment and abrasive damage. On the contrary, the flexible boxes are perfect for packaging and shipping products.

A partial finish is always an excellent idea for getting into the whole styling approach. Plus, the sales will skyrocket if you can get a rigid box design that is partially finished up to perfection. A partially finished rigid is very easy to identify. The design tells it all.

. You will see that the box has no proper finishing from the inside. This is a great strategy for showcasing your products within the box.

No other packaging type can beat luxury rigid boxes in terms of marketing. Considering the overall build quality of a rigid box, it is pretty clear why marketing over it is a great idea.

The box is usually four times thicker and more durable than a regular cardboard box. This eventually means that the product safety dynamics of these boxes are also better. As a result, any stuff embossed or printed over these boxes will last out there for quite some time. This is where marketing gets on the spot.

The go-green initiative has finally taken over the world. According to this initiative, retailers and responsible manufacturers like TPS can focus on reducing their carbon imprint with rigid boxes wholesale. There are many ways one can do all of this. However, most corporate-level retailers are focusing on achieving this feat through packaging.

For instance, plastic packaging is responsible for generating the most non-degradable waste on the planet. There is a certain limit up to which the plastic can be recycled. But on the other hand, packaging, like our green rigid box, is super durable and sustainable at the same time.

There is no restriction on the material for manufacturing a rigid box. With the advancement in technology, the boxes are getting new and improved shapes. Plus, the build materials of the boxes are also changing dramatically. Major credit for this goes to the luxury industry, which is always experimenting with these specific boxes.

Generally, hard cardboard is the primary and the most widely used material in their manufacturing. The cardboard is a great sustainable option that offers an exceptional level of durability. Plus, all the modern printing dynamics are also available for cardboard-based boxes.

The Packaging Spot innovates new and improved prototypes of rigid boxes that can heighten the impact of your products in the market in the most impactful manner. Reach us today and make the most out of our regularly offered sales and discounts.